How to Find China Private Label Manufacturer ?

December 8, 2025

Top China Trade Trends to Watch Out for in 2026

December 18, 2025D2C Brand Sourcing in China: Your Ultimate Guide

Key Highlights

- Cost-Effective D2C brand Sourcing in China: China sourcing offers a significant cost advantage, allowing Direct-to-Consumer (DTC) model brands to achieve higher profit margins.

- Finding Partners: Locating a reliable Chinese manufacturer is a crucial step, which can be done through online marketplaces, trade shows, or sourcing agents.

- Quality is Key: Implementing strong quality control measures, including sampling and factory audits, is essential for maintaining brand standards.

- Navigating Logistics: A well-managed supply chain is vital for handling shipping, customs, and fulfillment directly from China to your customers.

- Overcoming Hurdles: Be prepared to manage challenges like communication barriers and potential supply chain disruptions.

Introduction

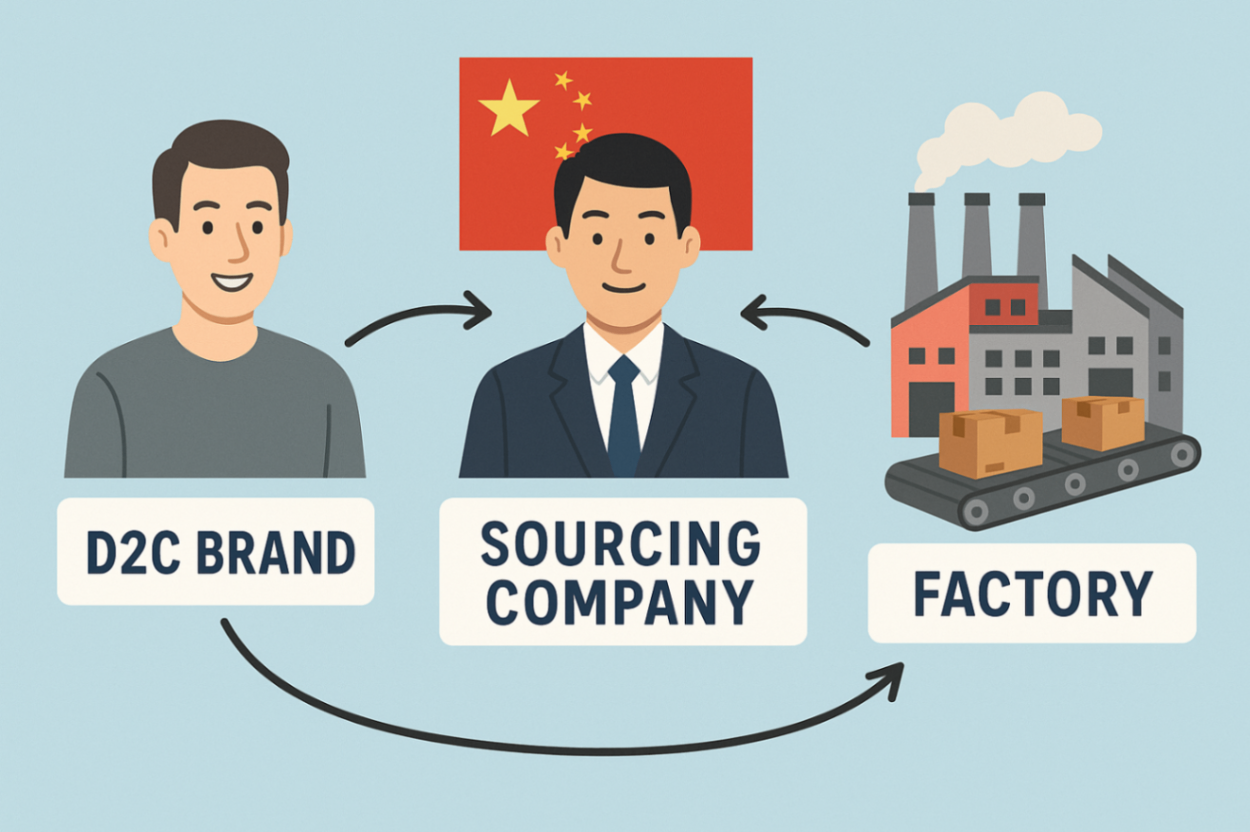

The Direct-to-Consumer (D2C) model is transforming e-commerce, allowing brands to connect directly with their customers. A key strategy fueling this growth is China sourcing. By tapping into China’s vast manufacturing network, you can access a wide product category range and optimize your supply chain. This guide will walk you through everything you need to know, from finding the right partners to getting your products into the hands of your customers.

Why D2C Brands Source from China

Many D2C brands choose to source from China for several compelling reasons. The country’s immense production capacity and significant cost advantage make it an attractive hub for manufacturing. This allows businesses to produce goods at a lower price point, which can be passed on to consumers or reinvested into the company.

Effective supply chain management is another driver, as China’s infrastructure is well-equipped for global reach. For D2C brands looking to scale quickly and compete on an international stage, sourcing from China provides a powerful foundation for growth. Below, we’ll explore these benefits in more detail.

Advantages for UK-Based Businesses

For any business, including those based in the UK, sourcing from China offers a direct path to higher profit margins. The lower manufacturing costs allow you to offer competitive pricing in your home market while protecting your bottom line. This financial advantage is a game-changer, especially for new and growing D2C brands.

Furthermore, Chinese manufacturers have a highly refined production process. Their experience and infrastructure contribute to remarkable supply chain efficiency, meaning they can often handle large orders and quick turnarounds. This reliability helps you keep your products in stock and your customers happy.

Ultimately, this combination of cost savings and production power lets you scale your business more effectively. You can invest the money you save back into marketing, product development, or other key areas, giving you a distinct edge over competitors who may be using more expensive, traditional models.

Market Trends and Growth in China

In recent years, China’s role as the “world’s factory” has only solidified. The country’s manufacturing landscape is incredibly diverse and advanced, capable of producing a vast array of goods. This growth is supported by a skilled workforce and a government that has invested heavily in infrastructure, making it a hub for global trade.

Changes in global consumer behavior have also played a part. As more people shop online, the demand for unique and affordable products has skyrocketed. D2C brands are perfectly positioned to meet this demand, and Chinese manufacturers provide the scale and speed needed to keep up.

The digital revolution has made it easier than ever for businesses to connect directly with suppliers in China. This direct line of communication, combined with the country’s manufacturing prowess, continues to drive the trend of D2C brands sourcing from the region.

Product Categories Dominating D2C Sourcing

A wide product range is available when sourcing from China, making it a versatile option for nearly any D2C brand. While almost any product category is possible, a few consistently dominate the landscape. These are often items that benefit from China’s mass production capabilities and cost efficiencies.

Many global brands and startups alike turn to China for private label opportunities in these popular niches. Sourcing a pre-existing product and adding your own branding is a fast and effective way to get to market. Some of the most common categories include:

- Electronics and gadgets

- Fashion, apparel, and accessories

- Home goods and kitchen supplies

- Toys and children’s products

- Jewelry and beauty products

- Personal care,Skincare and Haircare.

Whether you’re looking to create something entirely new or improve upon an existing item, you’ll likely find a specialized manufacturer ready to help. The sheer variety allows you to build a diverse and appealing product line for your customers.

Key Steps to Source Products for Your D2C Brand

Embarking on your China sourcing journey requires a clear and organized plan. A well-defined sourcing strategy is the foundation for success, ensuring you find the right products and partners for your brand. This process helps you navigate the complexities of international manufacturing and build supply chain efficiency from day one.

From initial research to final negotiations, each step is crucial for a smooth experience. The following sections will break down how to create your strategy, find reliable suppliers, and establish effective communication to get your D2C brand on the right track.

Defining Your Sourcing Strategy

Before you even start looking for suppliers, the first step is to define your sourcing strategy. This means having a crystal-clear idea of what you want to create. What are your product specifications? Think about materials, dimensions, features, and quality standards. The more detailed you are, the easier it will be to find a manufacturer that can meet your needs.

A strong sourcing strategy also involves outlining your business goals. Determine your target cost per unit, desired profit margins, and the initial order quantity you’re comfortable with. This information is critical for negotiating with suppliers and managing your budget effectively.

Finally, consider your long-term supply chain management plan. How will you scale production as your brand grows? Thinking about these factors upfront will help you choose a partner who can grow with you, creating a stable and efficient supply chain for the future.

Researching and Shortlisting Suppliers

Once you have a strategy, it’s time to find potential manufacturing partners. The internet is a vast resource, but it can be overwhelming. The goal is to create a long list of potential suppliers and then narrow it down to a shortlist of the most promising candidates.

Start your search on large online platforms where you can filter by product category and other criteria. As you find potential partners, start digging into their background. Look for supplier credentials, read reviews, and see how long they’ve been in business. This initial research helps weed out inexperienced or unreliable options. From there, you can narrow down your list to find the right supplier by using platforms such as:

- Alibaba

- Global Sources

- Made-in-China.com

- or a trusted Sourcing Company

The final step is to analyze their production process and capabilities to ensure they align with your needs. Don’t be afraid to ask for detailed information before moving forward.

Initiating Contact and Communication

Effective communication is the cornerstone of a successful manufacturing partnership. When you first reach out to potential suppliers, be prepared with detailed information about your product and requirements. Clear communication from the start prevents misunderstandings and costly mistakes down the line.

Keep in mind that language barriers can be a challenge. Write your emails in simple, direct language and use bullet points to break down complex ideas. Including images or diagrams of your product is a great way to visually convey your specifications and overcome potential translation issues.

Pay attention to the supplier’s responsiveness and level of customer service. A reliable partner will be professional, answer your questions thoroughly, and be willing to work with you. Slow or vague responses can be a red flag, indicating poor organization or a lack of interest.

Finding Reliable Manufacturers in China

Finding a reliable Chinese manufacturer is one of the most important steps in your sourcing journey. It’s not just about finding the cheapest option; it’s about finding a trustworthy partner who can consistently deliver a high-quality product. This requires a thorough vetting process to avoid potential problems.

To ensure you’re working with a legitimate company, you should verify their business licenses and consider conducting a factory audit. These steps give you peace of mind and help establish a strong foundation for your partnership. Let’s explore how you can identify and evaluate the best manufacturers for your brand.

Using Online Marketplaces and Directories

Online marketplaces are an excellent starting point for finding manufacturers. These platforms connect you with thousands of suppliers across countless industries, making them an invaluable resource for any D2C brand. They allow you to search for specific products and filter results to find what you need.

While these sites are convenient, it’s important to approach them with a discerning eye. Not all suppliers listed are created equal. Look for verified suppliers or those with high ratings and positive reviews. The best manufacturers will often have a “Gold Supplier” status or similar verification, indicating they have undergone a vetting process. Some of the most popular online marketplaces and directories include:

- Alibaba

- AliExpress

- Global Sources

- Made-in-China.com

These platforms are a great place to start your search, but always perform your own due diligence. They are a tool to help you find potential partners, not a guarantee of quality.

Evaluating Supplier Credentials

Once you have a shortlist of potential manufacturers, it’s time to evaluate their credentials. This is a critical step to ensure you are partnering with a legitimate and capable business. Start by asking for a copy of their business licenses to confirm they are officially registered with the Chinese government.

Next, inquire about their years of experience and any certifications they hold. Certifications like ISO 9001 indicate that a manufacturer adheres to international quality management standards. Depending on your product, you might also look for specific approvals like CE or FDA. A supplier’s willingness to provide this documentation is a good sign of their professionalism.

Don’t just take their word for it. You can often verify business licenses and certifications through third-party services. Taking the time to properly check supplier credentials can save you from costly headaches, production delays, and quality issues in the future.

Visiting Trade Shows and Wholesale Markets

While online research is powerful, nothing beats meeting potential partners in person. Visiting trade shows in China is a fantastic option for connecting directly with manufacturers. These events allow you to see products firsthand, ask detailed questions, and build a personal rapport that is difficult to achieve over email.

Popular trade shows attract thousands of suppliers under one roof, making them incredibly efficient for sourcing. You can compare different manufacturers in your niche and get a feel for their quality and professionalism. It’s also a great way to spot emerging trends and discover new products. Some key trade shows to consider are:

- The Canton Fair in Guangzhou

- The Yiwu Commodities Fair

- East China Import and Export Commodity Fair

Even local trade shows can be valuable. Attending these events gives you confidence in your sourcing decisions and helps you foster stronger, more transparent business relationships from the very beginning.

Choosing the Right Sourcing Agents in China

If navigating the world of Chinese manufacturing feels overwhelming, you don’t have to do it alone. Sourcing agents are professional service providers who act as your local partner on the ground. They can manage the entire procurement process, from finding suppliers to coordinating shipping.

Selecting the right sourcing agent in China is a strategic decision that directly impacts product quality, pricing transparency, and supply chain reliability. A trusted sourcing partner like Nexofetch will have deep factory networks, strong negotiation capabilities, in-house quality control, multilingual communication skills, and proven export experience in your product category. Look for agents who provide end-to-end support—from supplier verification and sampling to compliance checks, production oversight, and logistics coordination—while maintaining full visibility of costs and supplier information. The right sourcing agent doesn’t just connect you to factories; they safeguard your brand, ensure operational efficiency, and help you scale globally.

Working with an agent can dramatically improve your supply chain management and reduce risks, especially if you’re new to sourcing from China. However, it’s important to choose the right one. Let’s look at what these agents do and how to find a reliable partner.

What Sourcing Agents Do

Sourcing agents are your boots on the ground in China, handling the time-consuming tasks involved in procurement. Their primary role is to streamline your supply chain by finding and vetting reliable manufacturers that match your specific product needs and quality standards. This saves you an immense amount of time and effort.

Beyond finding suppliers, agents offer a wide range of services designed to ensure customer satisfaction. They can assist with price negotiations, manage communication to overcome language barriers, and oversee the production process. Many also provide private label services, helping you with custom packaging and branding to make your product unique.

From quality inspections to logistics coordination, a good sourcing agent manages every detail. Their goal is to create a seamless and efficient process, allowing you to focus on growing your business while they handle the complexities of manufacturing.

How to Assess Sourcing Agent Reliability

Choosing the right sourcing agent is just as important as choosing the right manufacturer. The reliability of these service providers can make or break your sourcing experience. A key indicator of a trustworthy agent is their years of experience. An established agent will have a deep network of trusted suppliers and a thorough understanding of the manufacturing landscape.

Transparency is another important factor. A reliable agent will be open about their processes, supplier relationships, and fee structure. Ask for references or case studies from past clients to get a sense of their track record. When evaluating an agent, consider the following:

- Their experience in your specific product niche

- Client testimonials and reviews

- Their communication style and responsiveness

Ultimately, you are looking for a strategic partner, not just a middleman. Take the time to interview several agents and choose the one that best understands your brand’s vision and needs.

Cost Structures and Fees

Understanding the cost structures of sourcing agents is essential for managing your cash flow. Agents typically use a few different models for their fees, and it’s important to know which one works best for your budget and business needs. Some may charge a flat fee per project, while others take a commission based on your order value.

The most common method is a commission, often ranging from 5% to 10% of the factory price. This model aligns the agent’s interests with yours, as they are incentivized to negotiate a good price. Others may offer an all-in-one service package for a set fee, which can simplify budgeting. Be wary of agents who ask for large upfront fees with no clear deliverables.

A transparent agent will clearly outline their charges so there are no surprises. Discussing these fees upfront is key to maintaining a healthy partnership and ensuring your supply chain efficiency is not compromised by hidden costs.

| Fee Structure | How It Works | Best For |

|---|---|---|

| Commission-Based | Agent charges a percentage (e.g., 5%) of the total order value. | Brands that want the agent to negotiate lower prices. |

| Flat Fee | A fixed fee is charged per order or per project. | Businesses with clear, consistent orders and a predictable scope of work. |

| Hybrid Model | A combination of a fixed fee and a smaller commission. | Complex projects that require extensive management and ongoing support. |

Managing Product Quality When Sourcing from China

Maintaining high product quality is non-negotiable for any D2C brand. When sourcing from China, you are entrusting your brand’s reputation to a manufacturing partner thousands of miles away. Therefore, establishing a robust quality control process is absolutely essential to ensure you meet your customers’ expectations.

Setting clear quality standards from the beginning and consistently monitoring production are the keys to success. Without proper oversight, you risk receiving subpar products that can damage your brand and lead to financial losses. Let’s dive into the best practices for ensuring your products are made to your specifications.

Inspection Protocols and Certifications

The first step in managing quality is to define your quality standards in a detailed document. This should outline all your specifications, from materials and colors to dimensions and functionality. This document becomes the foundation for your inspection protocols, giving your supplier a clear benchmark to follow.

Next, establish clear inspection protocols. This means deciding at which stages of production you want to check for quality—for example, during production and before shipping. You can also look for manufacturers with existing certifications, which demonstrate a commitment to quality. Depending on your product, you may need to ensure compliance with standards such as:

- ISO 9001 (General quality management)

- CE Marking (For products sold in Europe)

- FDA Approval (For food and medical products sold in the U.S.)

A factory audit is another powerful tool. This involves an on-site visit to assess the manufacturer’s capabilities, equipment, and internal quality processes. This gives you confidence that they can consistently meet your standards.

Sampling and Product Validation

Never commit to a large order without first seeing a sample. The sampling stage is your first real opportunity to assess product quality. A reliable manufacturer should be willing to provide samples, though you will likely have to pay for them. When you receive a sample, inspect it meticulously to ensure it meets every one of your specifications.

Product validation doesn’t stop with your own inspection. If possible, get the sample into the hands of potential customers to gather early customer feedback. Do they like the feel of it? Does it function as expected? This feedback is invaluable for making final tweaks before you begin mass production.

If the first sample isn’t perfect, don’t be discouraged. It’s common to go through a few rounds of revisions. Use this process to refine your product and confirm that the manufacturer can execute your vision. This iterative process of sampling and validation is critical for ensuring the final product quality is exactly what you expect.

Working with Third-Party Quality Control

For many D2C brands, hiring a third-party quality control company is a great option. These companies act as your independent inspectors, providing an unbiased assessment of your products before they leave the factory. This service can be particularly valuable if you are unable to visit the factory yourself.

Third-party quality control inspectors can perform a range of services, from factory audits to pre-shipment inspections. They follow your specific quality standards and provide you with a detailed report, complete with photos and descriptions of any issues they find. This allows you to address problems directly with the manufacturer before the goods are sent.

While there is a cost associated with this service, the peace of mind it provides is often well worth it. Knowing that a professional has verified your order helps mitigate the risks of international sourcing and protects your investment and brand reputation.

Navigating Fulfillment and Logistics from China

Once your products are manufactured, the next challenge is getting them to your customers. Navigating fulfillment and logistics from China can be complex, involving multiple shipping methods, customs clearance, and last-mile delivery. A well-organized supply chain is crucial for ensuring your products arrive on time and on budget.

From choosing between air freight and sea freight to coordinating with partners who handle the paperwork, every decision impacts your timeline and costs. Let’s break down the key components of a successful D2C shipping strategy from China.

Shipping Methods for D2C Brands

D2C brands have several shipping methods to choose from when importing from China, each with its own balance of speed and cost. The two primary options are air freight and sea freight. Your choice will largely depend on your budget, timeline, and the nature of your products.

Air freight is the fastest option, with lead times typically ranging from a few days to a couple of weeks. It’s ideal for high-value, lightweight products or when you need to restock inventory quickly. However, this speed comes at a higher price. Sea freight, on the other hand, offers a significant cost advantage but is much slower, with transit times often taking 30-60 days. It’s best suited for bulkier goods and when you can plan your inventory well in advance. Common shipping options include:

- Air Freight: Fast but expensive.

- Sea Freight: Slow but cost-effective.

- Express Courier: Services like DHL or FedEx offer door-to-door service, simplifying logistics but at a premium cost.

Choosing the right shipping methods is a strategic decision that directly impacts your profit margins and ability to meet customer expectations.

Coordinating with Freight Forwarders

For most D2C brands, coordinating international shipping is not a DIY task. This is where freight forwarders come in. These companies specialize in managing logistics, acting as an intermediary between you and the shipping carriers. They handle the complexities of booking cargo space, preparing documentation, and tracking shipments.

A reliable sourcing company like Nexofetch doesn’t just help you find the right manufacturers, it can also provide international logistic solutions and becomes the operational bridge connecting production to your warehouse. With established partnerships across freight forwarders, customs brokers, and 3PL providers, a professional sourcing company can seamlessly manage the entire logistics chain. This includes coordinating container or air shipments with verified freight forwarders, handling export documentation, booking space on vessels, ensuring customs compliance (HS codes, duties, certifications), and monitoring transit timelines. For D2C brands importing from China, this means your finished goods can move directly from the factory floor to your target country and finally arrive at your warehouse or fulfillment center (such as Amazon FBA) without you having to manage multiple vendors. The sourcing company ensures efficient consolidation, transparent cost control, and smooth delivery—so brands can stay focused on product growth and customer experience rather than shipment complexities.

Effective supply chain management relies on clear communication with your freight forwarder. You’ll need to provide them with detailed information about your shipment, including the weight, dimensions, value, and origin/destination addresses. They will use this information to find the best shipping routes and rates for your needs.

A good freight forwarder is a valuable partner who can save you time, money, and stress. They have the expertise to navigate the world of international logistics, ensuring your goods move smoothly from the factory to your warehouse or fulfillment center.

Handling Customs and Import Regulations

Every international shipment must clear customs, and this process can be one of the trickiest parts of sourcing from China. Each country has its own import regulations, and failing to comply can result in significant delays, fines, or even seizure of your goods. Understanding these rules is critical.

Customs procedures involve declaring your goods, paying any applicable duties and taxes, and providing the correct documentation. Given the complex customs procedures, many businesses rely on their freight forwarder or a licensed customs broker to handle this process. These experts are familiar with the requirements and can ensure your shipment is cleared efficiently.

Mistakes in your customs paperwork can lead to your shipment being held, incurring extra storage costs and disrupting your supply chain. Investing in professional help to navigate import regulations is a wise decision that protects your business from unforeseen expenses and delays.

Optimizing Sourcing Costs for D2C Brands

While China offers a cost advantage, smart D2C brands are always looking for ways to optimize their spending further. Achieving lower costs isn’t just about haggling over the unit price; it’s about smart negotiation, avoiding unseen expenses, and building overall supply chain efficiency. A strategic approach can significantly impact your bottom line.

By understanding the total cost of sourcing, you can make informed decisions that benefit your business in the long run. The following tips will help you negotiate better deals, minimize hidden fees, and manage tariffs effectively.

Negotiation Tips to Lower Costs

Effective negotiation is a powerful tool for improving your profit margins. When speaking with potential manufacturers, don’t be afraid to discuss pricing, but approach it as a partnership rather than a confrontation. A good supplier relationship is mutually beneficial.

One of the best ways to gain a cost advantage is to demonstrate your potential for long-term business. Suppliers are often more willing to offer competitive pricing to a client they believe will place repeat orders. It’s also wise to get quotes from multiple suppliers to understand the market rate for your product. You can use this information as leverage, but always be respectful. Here are a few tips:

- Get quotes from at least three different manufacturers.

- Discuss long-term partnership potential.

- Ask about price breaks for larger order quantities.

- Be clear about your target price, but be realistic.

Remember, the goal of negotiation is to find a price that is fair for both you and the manufacturer, ensuring a sustainable and positive relationship.

Minimizing Unseen Expenses

The price you pay your manufacturer is only one part of the total sourcing cost. Many D2C brands are caught off guard by unseen expenses that can quickly eat into their profits. These can include shipping delays, unexpected tariffs, quality control fees, and currency conversion charges.

Careful planning is the best way to minimize these costs. Work with your freight forwarder to get a comprehensive quote that includes all potential charges, from shipping to customs clearance. Building a small buffer into your budget can also help you manage any unexpected issues without disrupting your cash flow.

Poor planning can also lead to excess storage costs if your goods arrive before you’re ready for them. By creating a detailed timeline and coordinating closely with all partners in your supply chain, you can avoid these costly surprises and keep your expenses predictable.

Tariffs and Their Impact on UK Imports

Tariffs are taxes imposed on imported goods, and they can have a significant impact on the total cost of your products. These taxes are a key component of global trade policies and can change based on political and economic factors. For D2C brands sourcing from China, understanding tariffs is crucial for accurate financial planning.

When calculating your cost of goods, you must factor in any applicable tariffs for UK imports from China. These costs are paid during the customs clearance process and can add a substantial percentage to your overall expenses. Failing to account for them can turn a profitable product into a loss-making one.

Effective supply chain management involves staying informed about current tariff rates and trade agreements. A customs broker or your freight forwarder can provide up-to-date information on these duties. By planning for tariffs, you can price your products correctly and maintain healthy profit margins.

Unique Sourcing Considerations for Fashion & Apparel D2C Brands

The fashion and apparel industry has its own set of challenges and opportunities when it comes to China sourcing. Because trends change so quickly, speed to market is critical. Additionally, consumers are increasingly demanding higher quality materials and more sustainable practices from the brands they support.

For a clothing D2C brand, this means paying close attention to manufacturing trends, material quality, and ethical standards. Success in this competitive space requires a sourcing strategy that is both agile and responsible. Let’s explore some specific considerations for fashion brands.

Trends in Clothing Manufacturing in China

The landscape of clothing manufacturing in China has evolved significantly in recent years. While it was once known primarily for low-cost mass production, many factories now specialize in high-quality, technical apparel for global brands. This shift has created new opportunities for D2C brands seeking premium craftsmanship.

One major trend is the move towards more flexible and smaller-batch production. Some manufacturers are now more willing to work with lower minimum order quantities, allowing smaller brands to test new styles without a huge financial commitment. This agility is perfect for the fast-paced world of fashion.

The product range available is also expanding. From sustainable fabrics to advanced performance wear, Chinese manufacturers are innovating to meet global demand. This allows fashion brands to create a diverse and modern product line that resonates with today’s consumers.

Ensuring Material Quality and Ethical Compliance

For fashion brands, material quality is paramount. The feel of the fabric and the quality of the stitching directly reflect on your brand. When sourcing, it’s essential to request fabric swatches and detailed specifications. You must also establish clear quality standards for every aspect of the garment, from the buttons to the seams.

In today’s market, ethical compliance is just as important. Consumers want to know that their clothes were made in factories that treat workers fairly. Ask potential manufacturers about their labor practices and any certifications they have, such as BSCI or WRAP. This commitment to ethical and sustainable practices can be a powerful part of your brand story. To ensure compliance, consider these steps:

- Request material composition reports.

- Ask for social compliance audit reports.

- Work with suppliers who are transparent about their supply chain.

By prioritizing both quality and ethics, you build a brand that customers can trust and feel good about supporting.

Common Challenges D2C Brands Face When Sourcing from China

While sourcing from China offers many benefits, it’s not without its difficulties. The biggest challenges often revolve around communication barriers, managing time differences, and dealing with potential supply chain disruptions. Being aware of these hurdles is the first step toward overcoming them.

A proactive approach is key to mitigating these risks. By planning ahead and establishing clear processes, you can navigate these common issues and build a resilient and efficient supply chain. Below, we’ll discuss practical solutions for these challenges.

Overcoming Communication Barriers

Communication barriers are one of the most common issues when sourcing from China. Even when a supplier representative speaks English, nuances can be lost in translation, leading to misunderstandings about product specifications or timelines. Overcoming these language barriers is critical for a smooth partnership.

The best strategy is to practice clear communication at all times. Use simple, direct sentences and avoid slang or jargon. Whenever possible, use visuals like photos, diagrams, and videos to explain what you need. Following up with a written summary of any phone or video calls also helps ensure everyone is on the same page.

Working with a sourcing agent or a translator can be a great way to bridge the communication gap. Their expertise can improve customer service interactions and reduce the risk of costly errors. Ultimately, patience and a commitment to clarity will pave the way for a successful relationship.

Time Zone and Lead Time Management

The significant time difference between Western countries and China requires careful planning. Real-time conversations can be difficult to schedule, so most communication will happen via email. Be prepared for a 12- to 24-hour delay in responses and factor this into your project timeline.

Managing lead times is another critical aspect of supply chain management. Production and shipping from China can take several months, so you need to plan your orders well in advance. This requires accurate sales forecasting to ensure you have enough stock without over-investing in inventory.

Effective inventory management is the key to balancing these long lead times. Use historical sales data to predict future demand and place your orders accordingly. Building some buffer stock can also help you avoid stockouts caused by unexpected production or shipping delays.

Mitigating Supply Chain Disruptions

Supply chain disruptions are an unavoidable risk in global trade. Issues like factory shutdowns, port congestion, or raw material shortages can all delay your orders and impact your business. While you can’t prevent every problem, you can take steps to mitigate their impact.

One of the best strategies is to build redundancy into your supply chain. This could mean identifying a backup manufacturer who can step in if your primary supplier has issues. Diversifying your shipping routes or using different logistics partners can also help improve supply chain efficiency and reduce your reliance on a single point of failure.

Maintaining open communication with your suppliers and logistics partners is also crucial. When you have a strong relationship, they are more likely to give you early warnings about potential disruptions, allowing you to make contingency plans. This proactive approach is key to maintaining customer satisfaction even when challenges arise.

Conclusion

In conclusion, sourcing from China offers D2C brands unmatched advantages, from cost efficiency to access to a vast range of products. As you embark on this journey, it’s crucial to define your sourcing strategy, thoroughly research suppliers, and maintain effective communication. Additionally, managing product quality and navigating logistics will further ensure a seamless operation. Don’t let the challenges deter you; with the right approach and resources, you can successfully tap into the growing Chinese market. If you’re ready to take the next step in optimizing your D2C brand’s sourcing strategy, get a free consultation with our experts today!

Frequently Asked Questions

How long does it take to import products from China for a D2C brand?

The total time can vary greatly, typically from 1 to 4 months. This depends on production lead times, the manufacturer’s production capacity, and your chosen shipping methods. Air freight is faster but more expensive than sea freight. Your entire supply chain, from order to delivery, will influence the final timeline.

What are the best platforms to source from China?

Online marketplaces like Alibaba and Global Sources are a great way to find a reliable Chinese manufacturer. These platforms list thousands of suppliers. For a more personal connection, attending local trade shows in China is another excellent option to meet potential partners face-to-face and inspect their products directly.

How can I ensure product quality when sourcing for my D2C brand?

To ensure product quality, start by setting clear quality standards and requesting samples. Implement strict inspection protocols at various production stages. Using a third-party quality control service to inspect goods before they ship is a highly effective way to verify that your standards have been met and protect your brand’s reputation.